The tried-and-true method of metal casting creates solid metal objects by pouring melted metal into a mold. Many industries use casting metal to produce detailed and durable parts which appear in numerous vehicle engines and decorative pieces. The metal casting technique works well for creating both large industrial equipment and small artwork objects.

The following article explains every stage of metal casting from original design through post-mold completion.

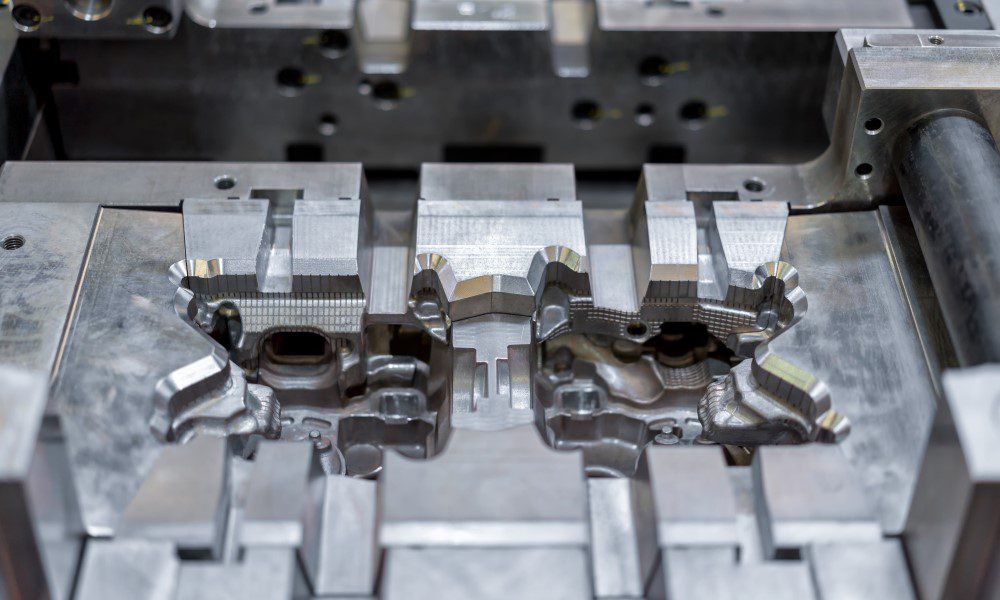

Step 1: Designing Both The Mold And The Pattern

A pattern that is an exact reproduction of the finished object is made at the beginning of the casting production process. Manufacturers use wax, wood, foam or metal to form the design at the start. We use the pattern to make a mold after melting the metal.

The casting industry uses various mold types based on their production methods.

- Sand molds serve well for producing large metal components.

- The investment casting process needs ceramic models to reproduce complex patterns.

- Metal molds enable continuous production because they maintain their strength without deterioration.

The key here is precision. Constructing the pattern well guarantees that cast items match design specifications and show no flaws.

Step 2: Melting the Metal

Manufacturers heat their chosen metal material (aluminum, bronze, or steel) in a thermal container. Every metal material needs a specific heat level to reach its melting point. When the metal reaches a liquid state all gases and contaminants are removed through filtration.

Special attention is given when pouring metal to prevent bubble formation and splashing. The liquid metal transfers into the mold before filling and shaping all parts of the design.

Step 3: Cooling and Solidifying

As the mold receives metal inside it starts to harden against heat loss. Your metal product needs the required amount of time to cool before you proceed based on its size and type. When cooling parts need special treatment to prevent defects such as cracks and uneven shape.

The proper temperature during cooling decides how strong and reliable a casting will be.

Step 4: Extracting the Solid Casting Material While Refining It

The finished mold comes out from the material when it reaches solid form. A metal mold serves several purposes while sand molds require complete replacement. The new metal product features excess material on discharge routes and entry channels that need to be cut off.

Final touches often include:

- The production method used to create a smooth product surface.

- Heating the metal changes its natural strength level.

- Machining for high-precision parts.

After processing the metal part undergoes the essential tests to verify it meets applicable standards for intended operational or aesthetic use.

The Role of Metal Casting Today

Because it can create intricate shapes that would be difficult or expensive to create using other techniques, metal casting is still crucial in manufacturing. It’s used in:

- Automotive engines and parts

- Aerospace components

- Industrial equipment

- Art and sculpture

The process demonstrates excellent results no matter what type of production you need and can handle any project design.

Conclusion

From the first spark in the furnace to the final polish, metal casting combines science and craftsmanship. Through this method metal pieces form our world little by little day after day.

You may also like

-

Powering Growth: How the MRO Supply Chain Drives Industrial Success

-

Metal Casting: The Timeless Engine of Modern Manufacturing

-

Keeping Singapore’s Skies Moving: Proponent’s Role in Reliable Aviation Support

-

How General Kinematics Can Revolutionize Scrap Processing

-

How Executive Career Coaching Unlocks Your Professional Potential